Aseptic Liquid Food Packaging Materials--Technical Insights and Application Guide

In today's food industry, aseptic liquid food packaging material plays a critical role in ensuring product safety and extending shelf life. From milk and juice to plant-based beverages and liquid condiments, aseptic packaging has become a standard solution for modern food manufacturers.

This article provides a detailed overview of the structure, production process, and key advantages of aseptic liquid food packaging materials, offering insights into their applications and future trends.

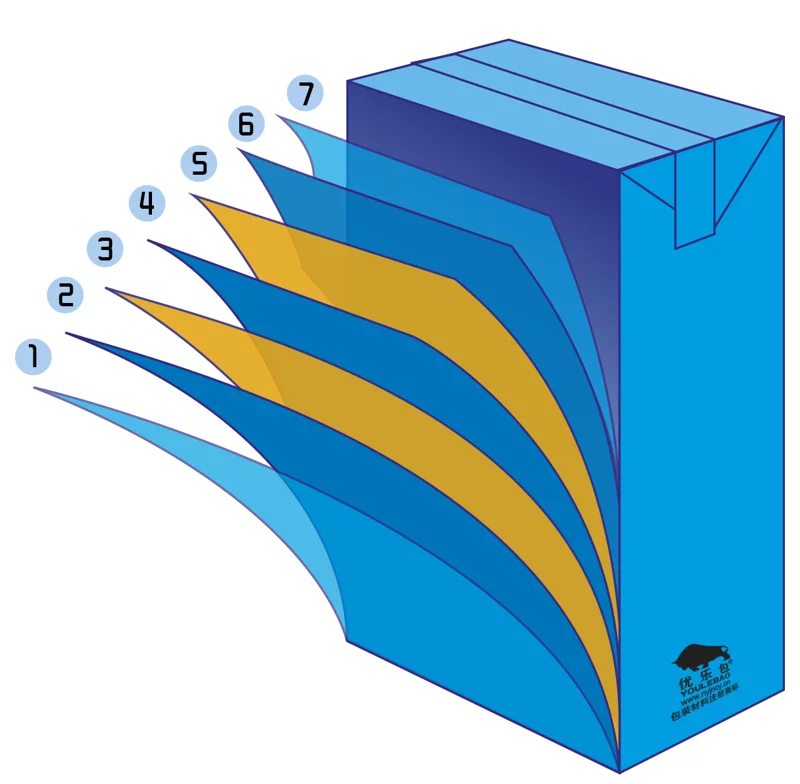

1. Material Structure: Multi-Layer Composition for Maximum Protection

Aseptic liquid food packaging materials typically consist of multiple layers, each serving a specific function:

- Paperboard: Provides structural strength and rigidity, while also serving as a printing surface for branding.

- Aluminum Foil: Acts as a shield against oxygen, light, and external odors, preventing oxidation and spoilage, thus extending shelf life.

- Plastic: Directly contacts the food, ensuring safety while providing an airtight seal.

This multilayer structure enhances durability and offers comprehensive food protection, making it a reliable choice for liquid food packaging.

2. Production Process: Precision Manufacturing from Roll to Finished Package

Aseptic packaging production is a highly automated process that involves several key steps:

- Material Lamination: Paperboard, aluminum foil, and plastic layers are combined using advanced technology to form a protective roll material.

- Forming & Filling: Under aseptic conditions, the laminated roll is shaped into a tubular structure, filled with the liquid product, and then hermetically sealed.

- Cutting & Final Packaging: The continuous tube is cut into individual packages and formed into the final shape, ready for distribution.

This efficient production process ensures consistency, cost-effectiveness, and high product reliability.

3. Application Fields: A Versatile Solution for the Liquid Food Industry

Aseptic liquid food packaging materials are widely used across various product categories:

- Dairy Products: Including fresh milk, long-life milk, and yogurt.

- Juices & Beverages: Such as 100% fruit juices, flavored drinks, and sports drinks.

- Plant-Based Beverages: Including soy milk, almond milk, and oat milk.

- Other Liquid Foods: Such as soups, broths, and liquid condiments.

Whether for ambient storage or refrigerated distribution, aseptic packaging provides optimal protection for liquid food products.

4. Sustainability & Environmental Benefits: A Step Towards Green Packaging

As environmental awareness grows, the sustainability advantages of aseptic packaging are becoming more prominent:

- Recyclability: Paperboard, aluminum, and plastic layers can be separated and recycled.

- Lightweight Design: Compared to traditional packaging, aseptic packaging is lighter, reducing carbon emissions during transportation.

- Resource Efficiency: Advanced manufacturing techniques minimize material waste and energy consumption.

5. Future Trends: Innovation Driving the Industry Forward

Aseptic packaging technology is continuously evolving, with several key trends shaping the future:

- Smart Packaging: Integration of QR codes, RFID technology, and digital tracking for enhanced consumer engagement and product traceability.

- Eco-Friendly Materials: Development of biodegradable and renewable packaging materials to reduce environmental impact.

- Customization & Personalization: Innovative packaging designs to meet the growing demand for brand differentiation and consumer engagement.

Conclusion

Aseptic liquid food packaging materials represent a significant innovation in the food industry, ensuring product safety, extending shelf life, and supporting sustainability efforts.

As a professional manufacturer, Jinniu Pak is committed to providing high-quality aseptic packaging solutions tailored to the needs of our customers. If you’re looking for reliable, cost-effective, and innovative packaging materials, feel free to contact us!

Maggie is the Export Manager at Henan Jinniu New Material Co., Ltd. With extensive experience, she has been crucial in expanding global reach and building strong client relationships. Maggie holds a Bachelor's degree in International Business and is committed to quality, innovation, and sustainability in the packaging industry.