Everything You Should Know About Aseptic Carton Packaging

Aseptic carton packaging is a type of packaging that is used to store and preserve perishable products, such as milk, juices, and other beverages, without the need for refrigeration or preservatives. The process involves sterilizing both the product and the packaging separately, then filling the product into the sterile packaging in a sterile environment. This method ensures that the product remains safe and free from microbial contamination throughout its shelf life.

The packaging itself is typically made from layers of paperboard, plastic, and aluminum, which together provide strength, a barrier to light, and protection from moisture and air. The combination of these materials helps to extend the shelf life of the product while maintaining its taste, nutritional value, and quality.

Aseptic carton packaging is widely used in the food and beverage industry because it offers a cost-effective, lightweight, and eco-friendly alternative to traditional glass or plastic containers. It also allows products to be distributed over long distances and stored for extended periods without the need for refrigeration.

Advantages Of Aseptic Carton Packaging

- Extended Shelf Life: Products packaged in aseptic cartons can be stored for extended periods, often several months, without refrigeration. This is due to the sterile packaging process, which prevents microbial growth.

- Preservation of Quality: The aseptic process maintains the taste, nutritional value, and overall quality of the product without the need for preservatives. The multi-layered packaging protects the contents from light, air, and contaminants.

- Eco-Friendly: Aseptic cartons are typically made from renewable resources like paperboard and are recyclable. They have a lower carbon footprint compared to glass or plastic packaging, contributing to environmental sustainability.

- Lightweight and Space-Saving: Aseptic cartons are lightweight and compact, making them easy to transport and store. Their rectangular shape optimizes storage space in warehouses and retail shelves.

- Cost-Effective: The extended shelf life and reduced need for refrigeration can lower distribution and storage costs. Additionally, the lightweight nature of aseptic cartons reduces transportation costs compared to heavier glass containers.

- Safety and Hygiene: The aseptic process ensures that both the product and packaging are sterile, reducing the risk of contamination. This makes aseptic packaging ideal for products that need to maintain high safety standards, such as dairy and juice products.

- Convenience: Aseptic cartons are easy to handle, open, and reseal, offering convenience to consumers. They are also available in various sizes, catering to different consumption needs.

- Global Distribution: The ability to store products without refrigeration makes aseptic cartons ideal for global distribution, particularly in regions with limited cold chain infrastructure.

Top Aseptic Carton Packaging Manufacturers Worldwide

- Tetra Pak International SA: A leading company in the aseptic packaging industry, Tetra Pak is renowned for its innovative solutions and sustainability initiatives. They offer a wide range of packaging formats suitable for various products.

- Amcor Ltd.: This global packaging leader provides a range of aseptic packaging solutions, focusing on sustainability and high-performance materials.

- SIG Combi bloc Group AG: A prominent player in the aseptic carton market, SIG Combi bloc is known for its flexible packaging solutions and efficient filling technologies.

- Mondi Group: Mondi is another key player in the aseptic packaging sector, offering innovative and sustainable packaging solutions across various industries.

- Great view Aseptic Packaging: Great view specializes in aseptic cartons, providing cost-effective and high-quality packaging solutions, particularly in emerging markets.

- IPI SRL (Cuisia Group): IPI offers a variety of aseptic carton solutions, focusing on dairy and beverage industries, with a strong emphasis on product safety and sustainability.

- Sealed Air Corporation: Known for its packaging innovations, Sealed Air provides aseptic solutions that ensure product freshness and safety.

- Schott AG: Schott focuses on high-quality glass packaging but has also ventured into the aseptic carton market, particularly in the pharmaceutical sector.

- Reynolds Group Holdings Limited: Reynolds Group is a major packaging company that includes aseptic packaging as part of its diverse product portfolio.

- WestRock: A leader in paper and packaging solutions, WestRock offers aseptic packaging options that prioritize sustainability and consumer convenience.

How To Find Right Aseptic Carton Packaging Supplier

1. Identify Your Requirements

- Product Compatibility: Determine the type of product you need to package (e.g., dairy, juice, pharmaceutical) and ensure the supplier can accommodate these specific needs.

- Volume and Scale: Consider the quantity you require and whether the supplier can meet both your current and future demands.

- Regulatory Compliance: Ensure the supplier adheres to relevant food safety and packaging regulations, especially if you operate in multiple regions.

2. Research and Shortlist Suppliers

- Industry Reputation: Look for suppliers with a strong reputation in the industry. Companies like Tetra Pak, SIG Combi bloc, and Amcor are well-known and trusted globally.

- Customer Reviews and Case Studies: Research customer feedback and case studies to gauge the supplier's reliability, quality, and service.

- Certifications: Verify certifications such as ISO9001:2015 quality management system, ISO45001:2018 occupational health and safety, ISO50001:2018 energy management systems, ISO22000:2018 safety management system, which indicate adherence to international standards.

3. Evaluate Technical Capabilities

- Technology and Innovation: Assess the supplier’s technology and whether they offer innovative packaging solutions like lightweight, eco-friendly, or customizable options.

- Filling and Sealing Equipment: Consider if the supplier can provide or recommend suitable filling and sealing equipment compatible with their packaging.

4. Request Samples and Conduct Trials

- Sample Testing: Request samples of their packaging to test with your product. Check for durability, ease of use, and overall compatibility.

- Pilot Runs: If possible, conduct pilot runs to evaluate the packaging's performance during production, transportation, and shelf life.

5. Assess Supply Chain and Logistics

- Geographical Reach: Consider the supplier’s ability to deliver products to your location reliably. Global suppliers may offer better logistics networks.

- Lead Times and Flexibility: Evaluate lead times and the supplier's flexibility in scaling production to meet demand fluctuations.

6. Review Cost and Value

- Pricing Structure: Compare pricing across different suppliers, considering both upfront costs and long-term value.

- Total Cost of Ownership: Include factors like shipping, storage, and potential waste in your cost assessment.

7. Visit Facilities if Possible

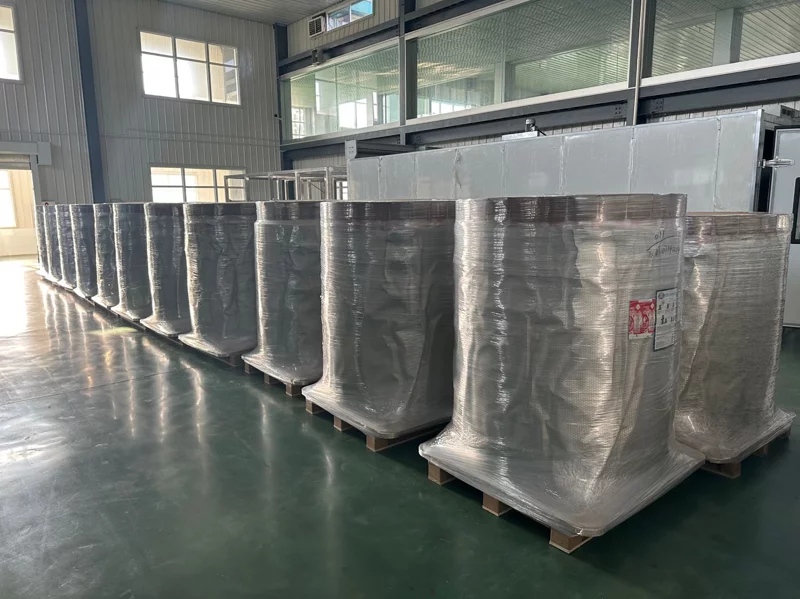

- Site Visits: If feasible, visit the supplier’s manufacturing facilities to assess their operational standards and capacity firsthand.

- Quality Control: Observe their quality control processes to ensure consistency and reliability.

8. Negotiate Terms and Build a Relationship

- Contract Negotiation: Negotiate terms, including pricing, delivery schedules, and service agreements.

- Long-term Partnership: Focus on building a long-term relationship with the supplier, which can lead to better pricing, priority service, and collaborative innovation.

9. Consider Sustainability

- Environmental Impact: Choose suppliers who prioritize sustainability, such as those offering recyclable or renewable packaging materials.

- Corporate Responsibility: Check the supplier's commitment to environmental and social responsibility.

10. Use Industry Networks and Trade Shows

- Trade Shows and Conferences: Attend industry events to meet suppliers in person, see product demonstrations, and discuss potential collaborations.

- Industry Associations: Utilize industry associations and networks to get recommendations for reliable suppliers.

Why Should You Consider an Aseptic Carton Packaging Supplier from China

Considering an aseptic carton packaging supplier from China can offer several advantages:

1. Cost Efficiency

- Lower Production Costs: China is known for its cost-effective manufacturing processes. Suppliers can often provide competitive pricing due to lower labor and production costs.

- Economies of Scale: Many Chinese suppliers operate at large scales, which can further reduce costs through economies of scale.

2. Advanced Manufacturing Capabilities

- Technological Expertise: Chinese manufacturers have increasingly invested in advanced technology and automation in packaging production, leading to high-quality, consistent output.

- Innovation: Many Chinese suppliers are at the forefront of packaging innovation, offering advanced features like sustainable materials and custom designs.

3. Customization and Flexibility

- Tailored Solutions: Chinese suppliers are often willing to customize packaging solutions to meet specific client needs, from design to material selection.

- Flexibility in Orders: They can accommodate a wide range of order sizes, from small batches to large-scale production, offering flexibility in meeting demand.

4. Global Supply Chain Integration

- Export Experience: Chinese suppliers are experienced in global trade and logistics, making it easier to integrate into your supply chain. Many are well-versed in international shipping regulations and standards.

- Strong Supply Chain Networks: The vast supply chain network in China ensures a reliable supply of raw materials and components, reducing the risk of delays.

5. Sustainability and Environmental Compliance

- Sustainable Practices: Many Chinese manufacturers have adopted environmentally friendly practices and materials, responding to global demands for sustainability.

- Certifications: Look for suppliers with international certifications like ISO9001:2015 quality management system, ISO45001:2018 occupational health and safety, ISO50001:2018 energy management systems, ISO22000:2018 safety management system, to ensure they meet global environmental standards.

6. Market Access and Strategic Location

- Proximity to Raw Materials: China’s strategic location gives it easy access to a wide range of raw materials, which can lead to faster production times.

- Access to Emerging Markets: Partnering with a Chinese supplier can help you gain better access to Asian markets, which are some of the fastest-growing consumer markets in the world.

7. Government Support and Incentives

- Export Incentives: The Chinese government offers various incentives to manufacturers that export products, which can result in cost savings for international clients.

- Belt and Road Initiative: China's Belt and Road Initiative has improved infrastructure and trade routes, facilitating smoother international transactions.

8. Quality Control

- Stringent Quality Standards: Many Chinese suppliers adhere to strict quality control measures, ensuring the packaging meets international standards.

- Continuous Improvement: The competitive nature of the Chinese market drives continuous improvement in product quality and manufacturing efficiency.

How about Henan Jinniu New Material Co., Ltd.

Henan Jinniu New Material Co., Ltd., established in 1998, is a leading Chinese manufacturer specializing in aseptic and flexible packaging solutions. With over 25 years of experience, they operate two state-of-the-art manufacturing facilities in Nanyang and DEng Zhou. The company is known for its advanced production equipment, strict quality control, and strong R&D capabilities. They hold multiple international certifications and serve a global clientele, offering customized, high-performance packaging solutions across various industries.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.